In today's highly competitive manufacturing industry, staying ahead of the curve is imperative for success. To achieve this, manufacturers constantly seek innovative solutions to streamline their operations, enhance productivity, and optimize their processes. Microsoft Dynamics 365 has emerged as a game-changer, rendering a range suite of tools and functionalities explicitly tailored for the manufacturing sector. In this blog, we will explore why Microsoft Dynamics 365 was chosen for the manufacturing industry, shedding light on how it can drive innovation and competitiveness in this dynamic sector.

The Digital Transformation Drive in Manufacturing

Digital transformation is reshaping every industry, and manufacturing is no exception. The following factors show the deep impact of digitalization on the manufacturing sector:

1. Smart Manufacturing

Digitalization has ushered in the era of smart manufacturing, where machines are interconnected and can communicate with each other. This enables predictive maintenance, reducing downtime and increasing production efficiency. Dynamics 365 leverages the Internet of Things (IoT) for predictive maintenance, ensuring machines remain in optimal condition.

2. Enhanced Collaboration

Digital transformation fosters collaboration across the manufacturing ecosystem. Dynamics 365 facilitates collaboration with suppliers, distributors, and customers. By sharing real-time data, manufacturers can coordinate production and respond swiftly to changing market demands.

3. Customer-centric Approach

Today's consumers expect products tailored to their needs and delivered quickly. Digitalization enables manufacturers to offer customized products efficiently. Dynamics 365's customer engagement and sales modules allow manufacturers to engage with customers, understand their preferences, and deliver personalized solutions.

DynaTech for Manufacturing - Cutting-edge IT Solutions for Manufacturing Industry

- Sales Cycle and Estimation

Effortlessly manage the complex sales process with our cutting-edge Microsoft Dynamics 365 solutions. From initial inquiries to accurate cost estimates to detailed project proposals, our integrated tools escalate your ability to secure projects. Benefit from streamlined communication, collaborative quoting, and efficient tracking to ensure your sales efforts are precise, persuasive, and successful.

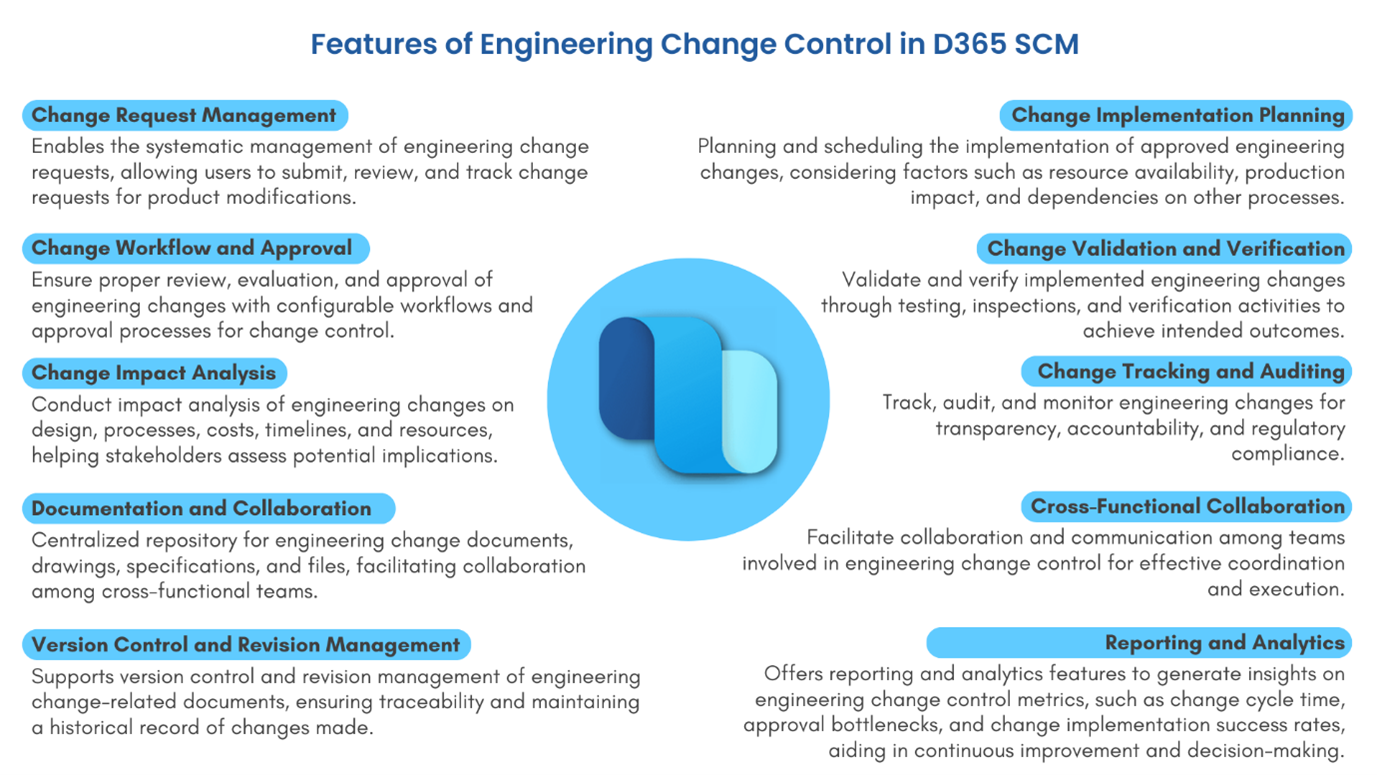

- Manage Project Change and Engineering Change Orders

Adapt swiftly to project changes with our robust Change Management solutions. Stay on top of evolving project requirements, effortlessly track modifications, and collaborate in real-time with stakeholders. Maintain project timelines and deliverables while ensuring project integrity, minimizing disruptions, and maintaining stakeholder satisfaction.

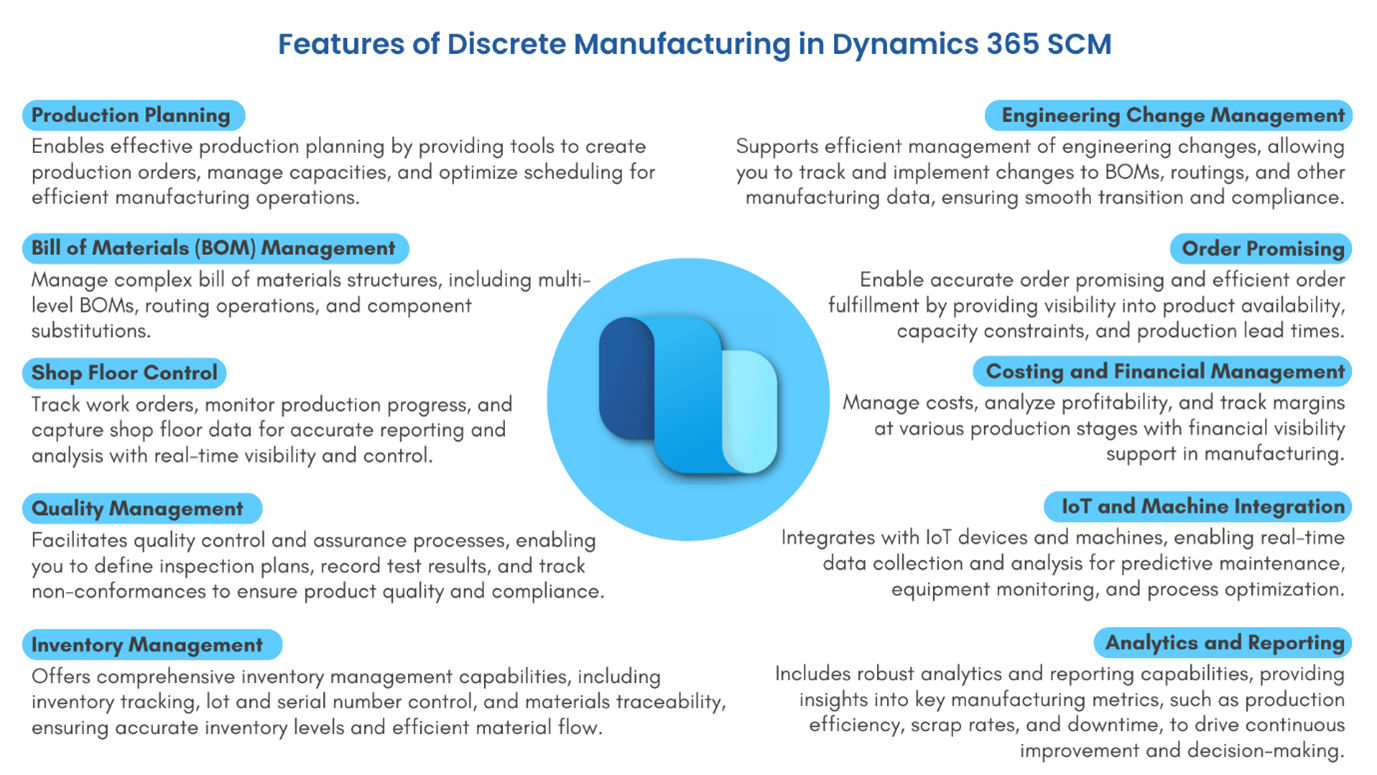

- Production Planning and Scheduling

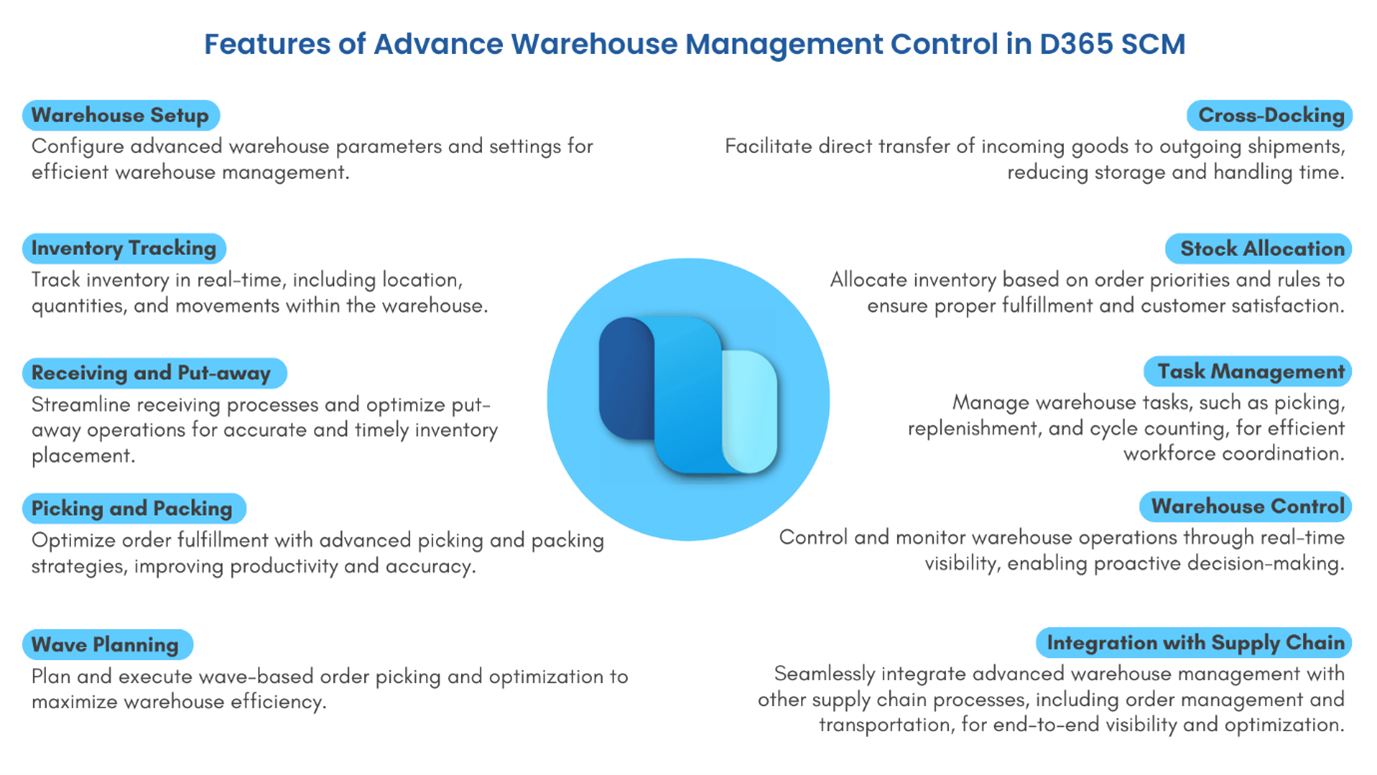

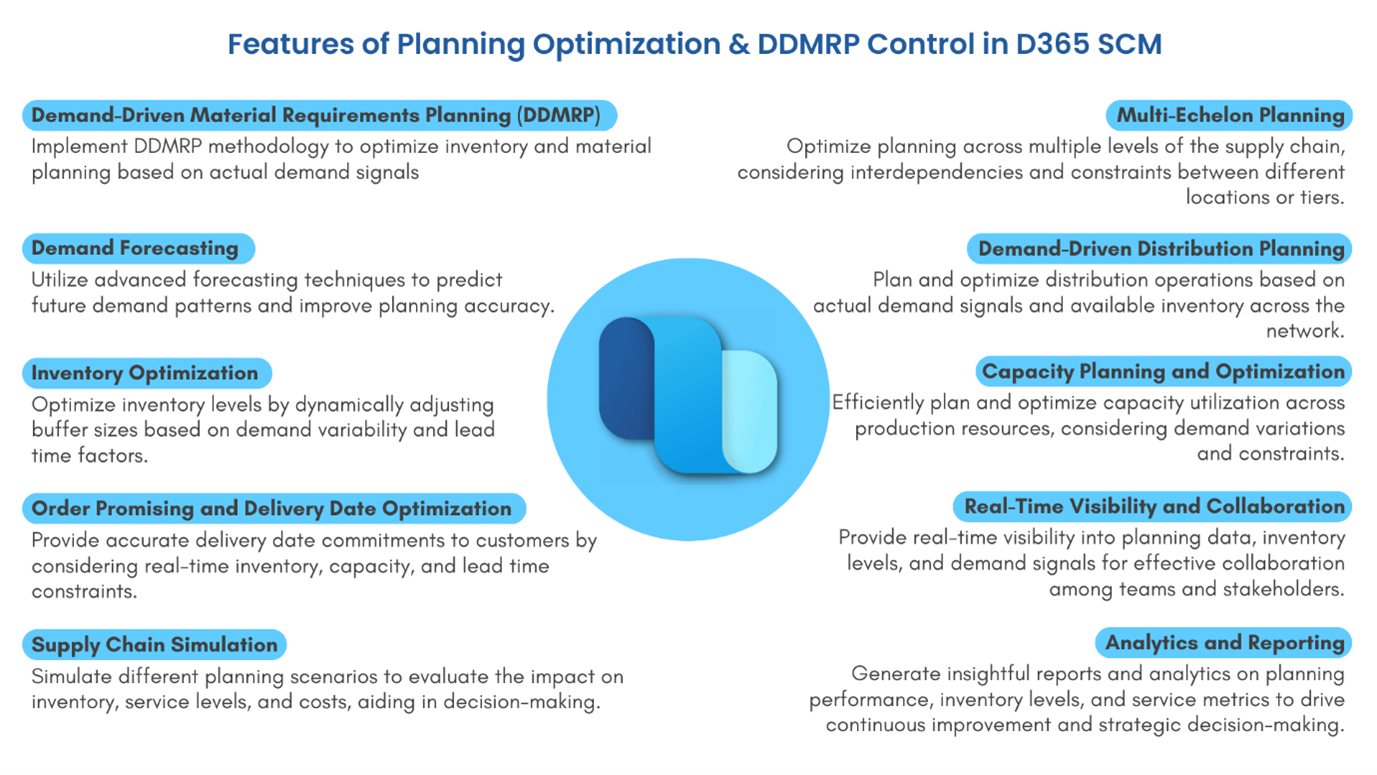

Leverage the power of Microsoft Dynamics 365 Project Operations and Project Accounting to create efficient project plans, track progress with the Project WBS (Work Breakdown Structure) and ensure timely execution of tasks. Seamlessly integrate with the shopfloor for real-time updates and agile scheduling, forecast demand accurately, and synchronize production with customer needs. - Supply Chain Optimization

Streamline your supply chain with cutting-edge Microsoft D365 Finance and Supply Chain Management to maximize inventory management, predict demand fluctuations, and identify potential risks while minimizing lead times. Our intelligent system helps you minimize carrying costs, prevent stockouts, and eliminate excess inventory. Experience improved collaboration with vendors and subcontractors through an integrated system to ensure timely deliveries and reduce production costs. - High-End Customization

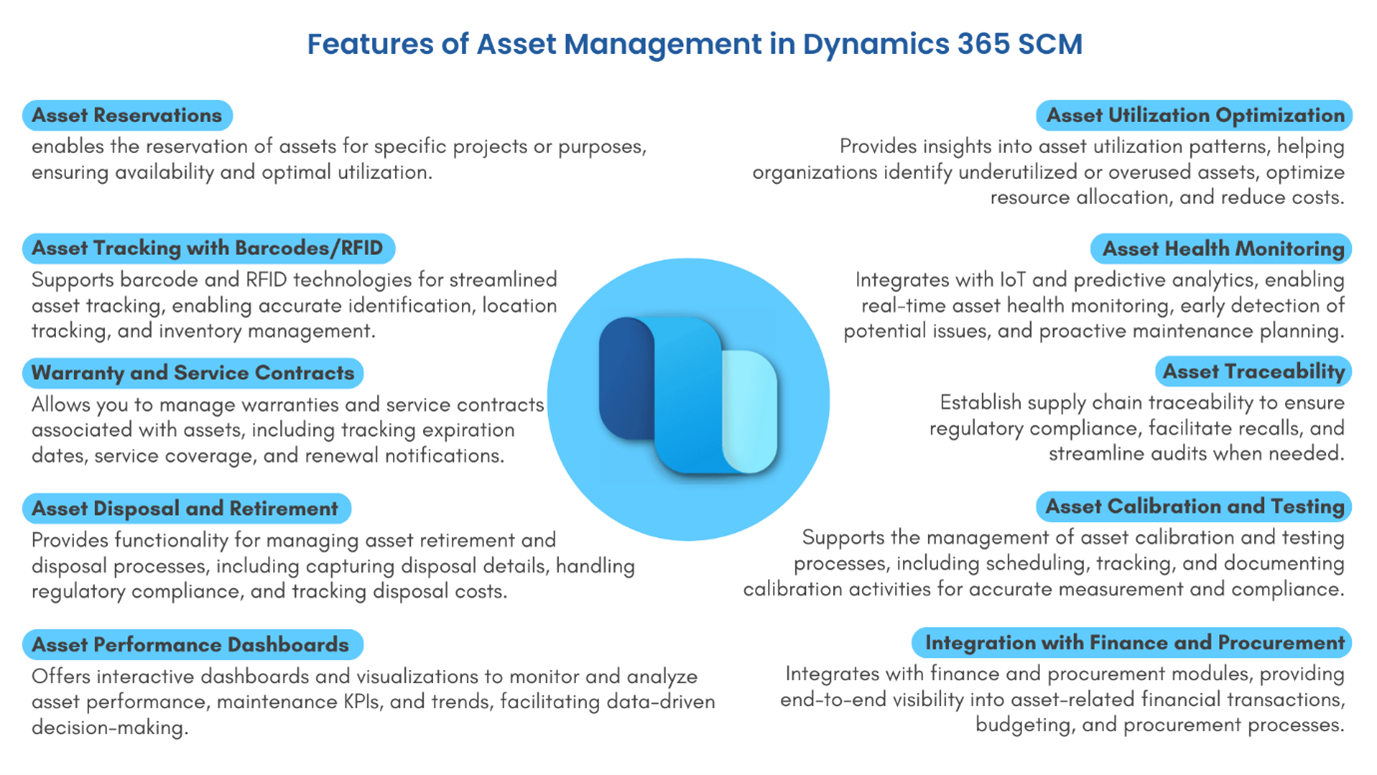

Embracing the demands of project-based ventures, we enable you to handle complex customization needs efficiently. Enhance your project offerings with OEM expertise, catering to custom-built solutions managed and tracked in the Asset Master system. Meet clients' unique demands and foster customer loyalty through top-notch personalized solutions. - Asset Management

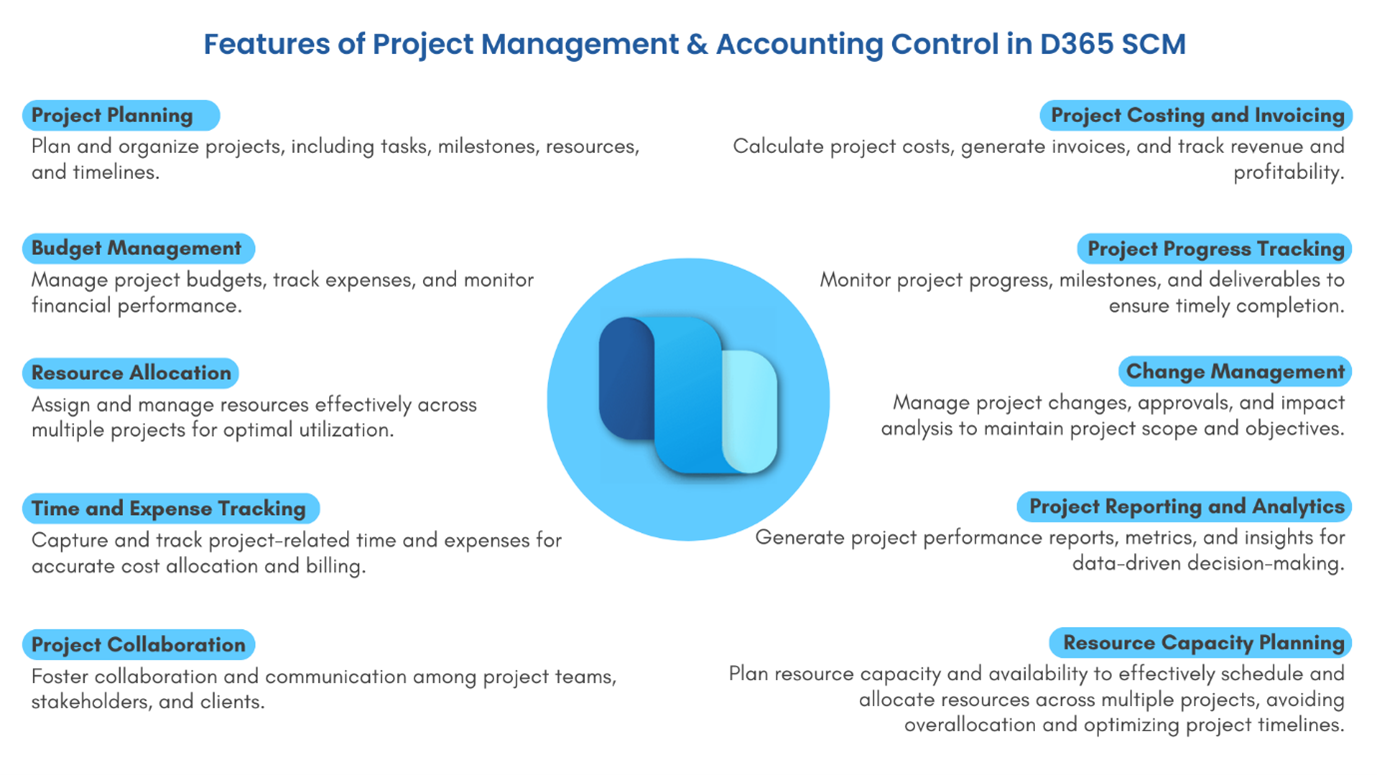

Harness the power of Microsoft D365 Field Services for streamlined asset management. Effectively track project assets and maintain schedules throughout their lifecycle for better decision-making. Optimize asset performance and reduce downtime while maximizing your return on investment. Our robust solutions help to easily track, maintain, and optimize your assets for peak performance. - Project Planning and Resource Management

Our team of professionals helps you unlock the full potential of your resources. With Microsoft D365 Project Operations, allocate and utilize resources effectively for optimal project execution. Seamlessly track employee skills, availability, and workload to assign the right tasks to the right people. Enhance workforce productivity, reduce bottlenecks, and ensure successful project -outcomes with data-driven resource management at your fingertips. - Cash Flow Management

Maximize your financial potential with Microsoft D365 Finance and Supply Chain Management. Streamline invoicing, payment processing, and financial tracking for improved liquidity and profitability. Stay on top of budgets and expenses with real-time insights, empowering you to make informed decisions and optimize cash flow throughout your project manufacturing journey. Experience financial stability and success with efficient money management at your disposal. - Risk Mitigation Strategies

Our data-driven approach empowers you to identify potential risks in their initial stages and implement effective mitigation strategies. Get real-time insights and reporting for proactive decision-making, ensuring your projects stay on track and within budget. With our expertise, you can navigate challenges, seize opportunities, and safeguard your project's success, delivering exceptional results to your clients and stakeholders. - Subcontractor Management

Our project manufacturing services include seamless subcontractor management facilitated by Microsoft D365 Sales. With a well-defined tender process and integration of third-party systems, we ensure efficient collaboration with subcontractors. From vendor selection to contract management, we simplify the entire process, allowing you to focus on core project activities: experience enhanced communication, timely deliveries, and cost-effective solutions. - Project Budgets and Accounting

Take complete control of your project finances with our comprehensive solutions. Get a project-specific accounting model designed for meticulous budget control. Track expenses in real time, monitor financial health, and generate insightful reports for informed decision-making. Stay on top of costs, optimize resource allocation, and ensure that your projects remain on budget and profitable every time. - Post-Project Analysis, Maintenance, and Support services

Leveraging Microsoft D365 Field Services, we conduct thorough analyses, identify areas for improvement, and implement tailored maintenance strategies to ensure asset longevity and performance. Continuous optimization and maintenance empower you to stay competitive, adapt to changing demands, and exceed expectations, securing lasting success for your project manufacturing endeavors. Our support services will help you maximize the long-term benefits of your project.

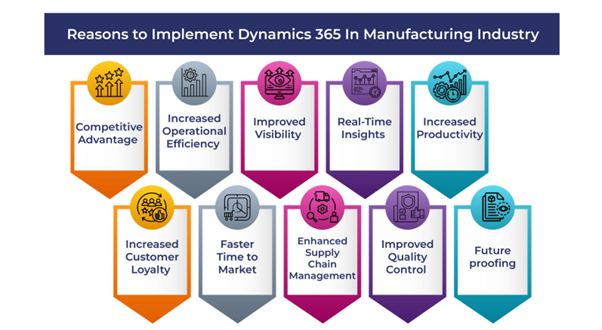

Reasons Manufacturing Firms Should Consider Dynamics 365 Implementation

Manufacturing firms should seriously consider implementing Dynamics 365 due to the below-mentioned reasons:

- Competitive Advantage

In a competitive market, manufacturers need every advantage they can get. Microsoft Dynamics 365 renders a comprehensive set of tools that can help streamline operations, reduce costs, and improve product quality. This translates into a significant competitive edge. - Increased Operational Efficiency

Efficiency is crucial in the manufacturing sector. Dynamics 365 helps manufacturers optimize processes, reduce waste, and maximize resource utilization. This results in reduced production costs and faster time-to-market.

- Improved Visibility

Enhanced visibility allows for better decision-making, as enterprises can track resources, monitor progress, and identify bottlenecks in real-time. With a clearer understanding of operations, manufacturing firms can optimize workflows and resource allocation for improved efficiency. - Real-Time Insights

Manufacturers can access up-to-the-minute data on production, inventory, and customer demands. This real-time visibility empowers teams to respond quickly to changing market conditions, adjust production schedules, and make informed decisions based on the latest information. - Increased Productivity

Microsoft Dynamics 365 offers tools for streamlining processes and automating routine tasks. This automation can lead to significant time and cost savings while reducing the risk of errors. By eliminating manual data entry and repetitive tasks, teams can focus on more strategic activities, ultimately increasing overall productivity. - Increased Customer Loyalty

Dynamics 365 enables businesses to provide better customer experiences by offering tailored products, shorter lead times, and improved communication. They can track customer interactions, preferences, and feedback to refine offerings and build long-lasting relationships. - Faster Time to Market

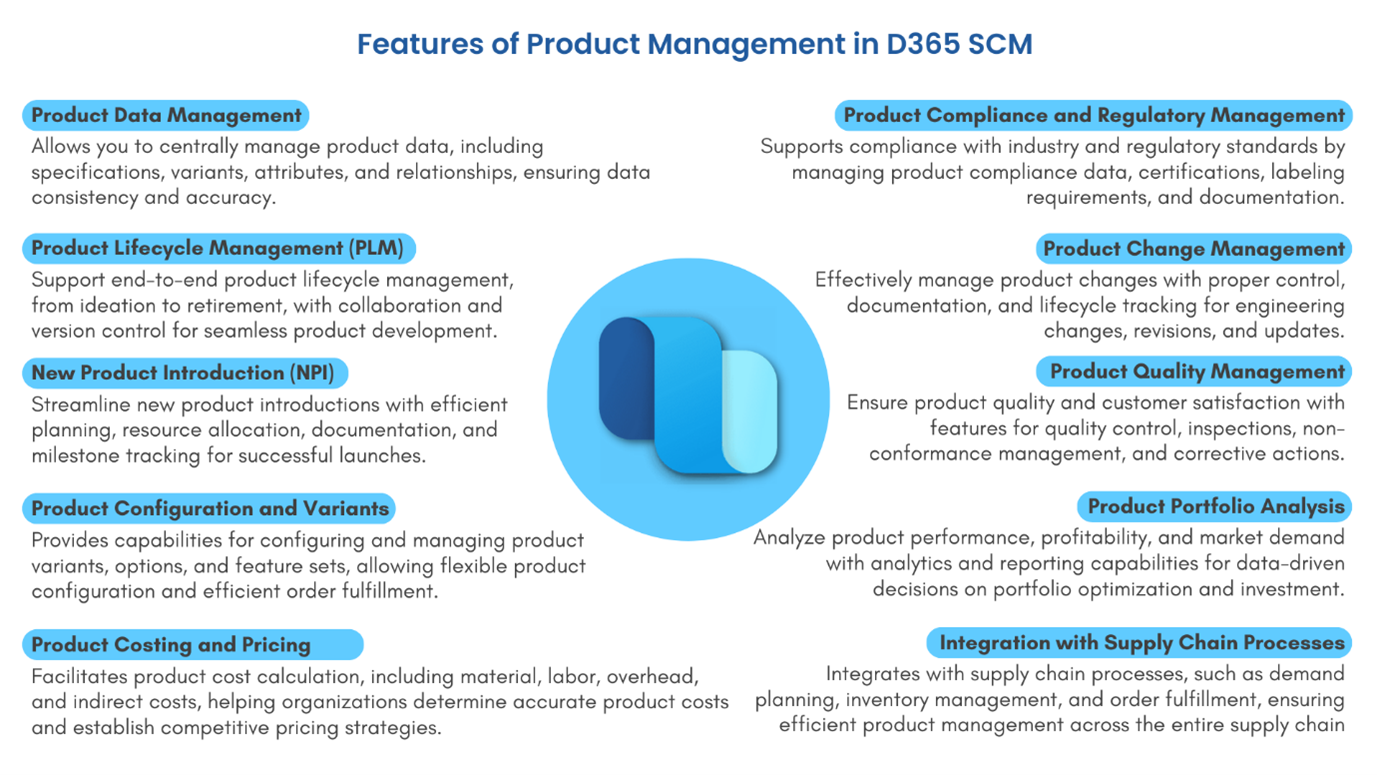

With Dynamics 365, enterprises can accelerate product development and delivery. The platform supports agile product development processes and helps manage complex projects efficiently. This agility can give your manufacturing firm a competitive edge by reducing time to market for new products or iterations. - Enhanced Supply Chain Management

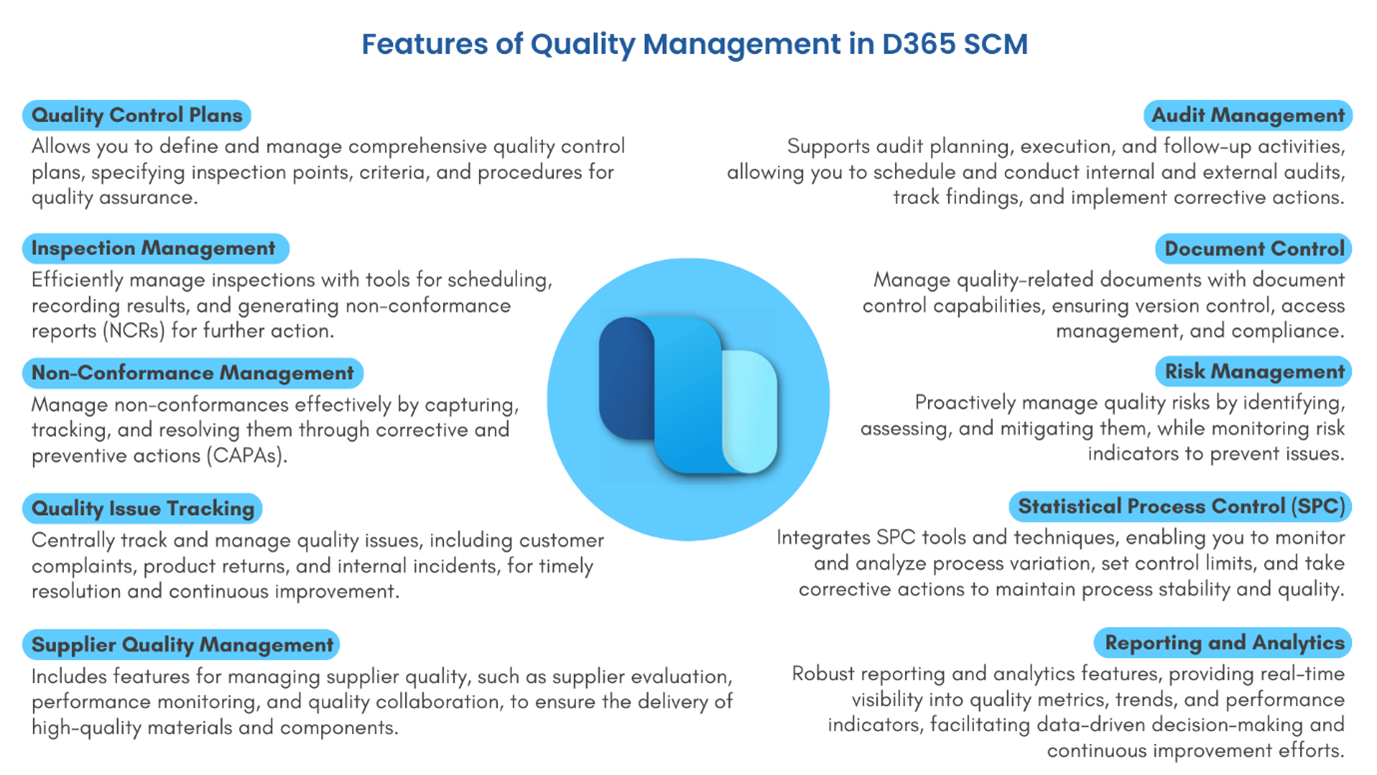

Dynamics 365 includes supply chain management capabilities that allow enterprises to optimize their supply chain, from procurement to distribution. This can result in reduced costs, minimized waste, and improved inventory management, ultimately leading to increased profitability. - Improved Quality Control

Manufacturing defects can lead to recalls and damage a brand's reputation. Dynamics 365's quality control and assurance modules help manufacturers maintain high-quality standards, reducing the risk of product recalls and customer complaints. - Future-proofing

The manufacturing industry will continue to evolve. Implementing Dynamics 365 ensures that manufacturers are prepared for future challenges and can adapt quickly to changing market conditions.

In A Nutshell

In conclusion, Microsoft Dynamics 365 has emerged as a transformative force in the manufacturing industry, offering next-level capabilities that empower manufacturers to thrive in today's ever-evolving landscape. By leveraging this robust platform, manufacturers can meet and exceed customer demands, rendering the highest quality products and services and maintaining cost-effectiveness.