Join the Revolution: Microsoft Copilot Paves the Way!

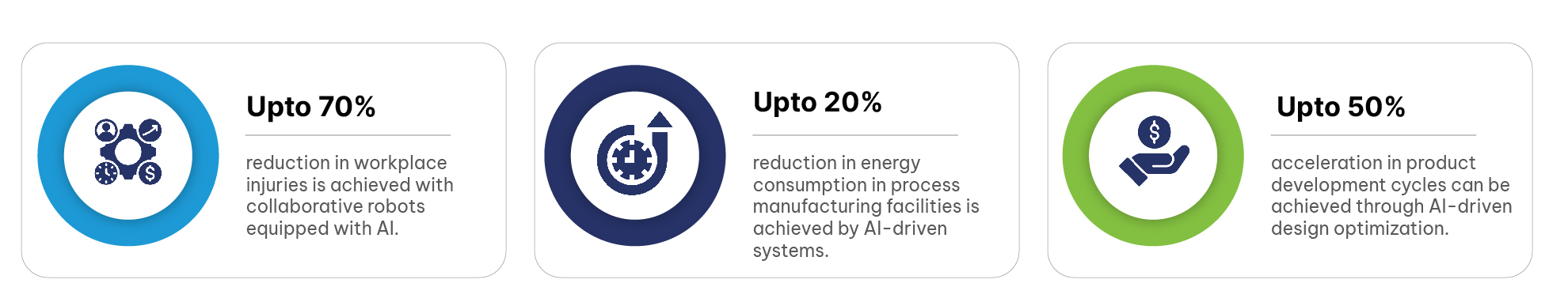

Increase Productivity, Reduce Downtime, and Ensure Workplace Safety.

Cutting-edge IT Solutions for Process Manufacturing Industry

- End-to-End Production Visibility

- Yield Planning

- Formula Management

- Co-products & By-products Management

- Optimized Picking and Batch Optimization

- Multi-dimensional Item Tracking

- Flexible Scheduling

- Production Costs Analysis

- Elevated Quality Control

- Routing, BOMs, and Employee Timekeeping

- Customized Product and Packaging Capabilities

- Supply Chain Optimization

- UOM Conversions

- Effective Lot Tracking

End-to-End Production Visibility

Gain real-time insights into your production processes, from raw materials to finished products. This transparency allows you to optimize production schedules, minimize downtime, and enhance resource allocation.

Yield Planning

Enhance resource utilization and minimize waste through comprehensive yield planning, considering purchase and sales prices based on batch attributes. Allocate resources efficiently, forecast production outcomes, and optimize yields with Microsoft Dynamics 365 for Finance and Operations.

Formula Management

Elevate product consistency through attribute tracking and formula adjustments. Manage standard, adjusted, and actual recipes, ensuring flexibility in ingredient quantities and precision in every batch. To enhance batch balancing, get a comprehensive view of your materials by tracking spillage, evaporation, consumption, shrinkage, etc., during production.

Co-products & By-products Management

Effortlessly manage multiple product outputs from a single production run. Get a versatile cost allocation system, track recurring by-products, and optimize resource utilization. With the flexibility to choose between manual, hard-allocated, or pro-rata cost allocation methods, take complete control of your production processes to boost efficiency and profitability.

Optimized Picking and Batch Optimization

Redefine order picking with Microsoft Dynamics 365 Commerce, optimizing batch sizes and ensuring balanced production runs based on batch attributes. Align inventory data, order intricacies, and warehouse operations for accurate and timely order fulfillment. Optimize batch sizes and batch balancing to ensure balanced production runs.

Multi-dimensional Item Tracking

Capture diverse product variations without the need for unique item codes or recipes. Easily consider factors like different container sizes, packaging types, variations to the main item, and track product lots, status, potency, catch weights, and nominal weights, ensuring precise inventory management, accurate costing, and seamless sales tracking.

Flexible Scheduling

Be it finite or infinite capacity scheduling, forward or backward scheduling, or incorporating recurrent items and rework, our system adapts seamlessly. With what-if scenario analysis, simply assess the impact of various sales scenarios. Manage your daily or minute-to-minute schedules, ensuring precise control and adaptability to demand and material supply changes.

Production Costs Analysis

Gain deep insights into production costs by analyzing various cost components. Our top-notch Microsoft Dynamics Process Manufacturing Solutions enable you to quickly identify cost-saving opportunities, optimize resource allocation, and enhance overall profitability.

Elevated Quality Control

Identify key quality issues using Pareto analysis and quarantine management to plan quality improvement initiatives proactively. Experience comprehensive quality management with raw material traceability, shelf-life management, expiry batch management, QA designations, and rebate tracking. With precision inventory methods like FIFO and FEFO, ensure quality and efficiency in every step of your production process.

Routing, BOMs, and Employee Timekeeping

Efficiently manage routing and Bills-of-Materials to optimize production workflows. Keep precise records of employee hours and attendance for accurate labor cost calculations, resource planning, and compliance with labor regulations.

Customized Product and Packaging Capabilities

Our Microsoft Dynamics for Process Manufacturing solution offers the ability to create customized products and pack item configurations, catering to individual customer preferences and boosting customer satisfaction. Tailor your offerings based on batch disposition code, sales order reservations, and unique customer demands, ensuring a personalized experience.

Supply Chain Optimization

Navigate complex supply chain dynamics seamlessly. Our solutions empower you to manage suppliers, track inventory levels, and synchronize demand with supply, enabling efficient production planning and minimizing bottlenecks.

UOM Conversions

Seamlessly track inventory stored in one unit of measurement and consumed during production in a different unit of measurement. Easily manage and store inventory in drums, rolls, pallets, super sacks, etc., while defining formulations in the most efficient unit of measurement.

Effective Lot Tracking

Easily search up to 100 pages immediately after a lot is generated or transacted. Simply track the finished goods back to their original ingredients in case of any off-spec quality issues. Not only this process, but manufacturers can also instantly track all the intermediates and finished goods and notify the stakeholders if the ingredient is found defective.

End-to-End Production Visibility

Gain real-time insights into your production processes, from raw materials to finished products. This transparency allows you to optimize production schedules, minimize downtime, and enhance resource allocation.

Yield Planning

Enhance resource utilization and minimize waste through comprehensive yield planning, considering purchase and sales prices based on batch attributes. Allocate resources efficiently, forecast production outcomes, and optimize yields with Microsoft Dynamics 365 for Finance and Operations.

Formula Management

Elevate product consistency through attribute tracking and formula adjustments. Manage standard, adjusted, and actual recipes, ensuring flexibility in ingredient quantities and precision in every batch. To enhance batch balancing, get a comprehensive view of your materials by tracking spillage, evaporation, consumption, shrinkage, etc., during production.

Co-products & By-products Management

Effortlessly manage multiple product outputs from a single production run. Get a versatile cost allocation system, track recurring by-products, and optimize resource utilization. With the flexibility to choose between manual, hard-allocated, or pro-rata cost allocation methods, take complete control of your production processes to boost efficiency and profitability.

Optimized Picking and Batch Optimization

Redefine order picking with Microsoft Dynamics 365 Commerce, optimizing batch sizes and ensuring balanced production runs based on batch attributes. Align inventory data, order intricacies, and warehouse operations for accurate and timely order fulfillment. Optimize batch sizes and batch balancing to ensure balanced production runs.

Multi-dimensional Item Tracking

Capture diverse product variations without the need for unique item codes or recipes. Easily consider factors like different container sizes, packaging types, variations to the main item, and track product lots, status, potency, catch weights, and nominal weights, ensuring precise inventory management, accurate costing, and seamless sales tracking.

Flexible Scheduling

Be it finite or infinite capacity scheduling, forward or backward scheduling, or incorporating recurrent items and rework, our system adapts seamlessly. With what-if scenario analysis, simply assess the impact of various sales scenarios. Manage your daily or minute-to-minute schedules, ensuring precise control and adaptability to demand and material supply changes.

Production Costs Analysis

Gain deep insights into production costs by analyzing various cost components. Our top-notch Microsoft Dynamics Process Manufacturing Solutions enable you to quickly identify cost-saving opportunities, optimize resource allocation, and enhance overall profitability.

Elevated Quality Control

Identify key quality issues using Pareto analysis and quarantine management to plan quality improvement initiatives proactively. Experience comprehensive quality management with raw material traceability, shelf-life management, expiry batch management, QA designations, and rebate tracking. With precision inventory methods like FIFO and FEFO, ensure quality and efficiency in every step of your production process.

Routing, BOMs, and Employee Timekeeping

Efficiently manage routing and Bills-of-Materials to optimize production workflows. Keep precise records of employee hours and attendance for accurate labor cost calculations, resource planning, and compliance with labor regulations.

Customized Product and Packaging Capabilities

Our Microsoft Dynamics for Process Manufacturing solution offers the ability to create customized products and pack item configurations, catering to individual customer preferences and boosting customer satisfaction. Tailor your offerings based on batch disposition code, sales order reservations, and unique customer demands, ensuring a personalized experience.

Supply Chain Optimization

Navigate complex supply chain dynamics seamlessly. Our solutions empower you to manage suppliers, track inventory levels, and synchronize demand with supply, enabling efficient production planning and minimizing bottlenecks.

UOM Conversions

Seamlessly track inventory stored in one unit of measurement and consumed during production in a different unit of measurement. Easily manage and store inventory in drums, rolls, pallets, super sacks, etc., while defining formulations in the most efficient unit of measurement.

Effective Lot Tracking

Easily search up to 100 pages immediately after a lot is generated or transacted. Simply track the finished goods back to their original ingredients in case of any off-spec quality issues. Not only this process, but manufacturers can also instantly track all the intermediates and finished goods and notify the stakeholders if the ingredient is found defective.

Experience Process Manufacturing Success With Microsoft Dynamics 365

The process manufacturing industry, renowned for its intricate production methods, faces many challenges, like complex supply chain management, stringent quality control requirements, and ever-evolving regulatory standards. It is also challenging to balance meeting customer quality demands and adhering to regulatory constraints while managing raw materials, inventories, and internal processes. Moreover, integrated tracking of raw materials, by-products, co-products, and finished goods, along with multi-dimensional product and inventory control, adds complexity to this sector.

Our partnership goes beyond mere technological implementation. We become your strategic collaborator, guiding you through the vast landscape of Microsoft Dynamics 365 for process manufacturing.

From streamlining logistics, production, and supply chains with real-time data to ensuring compliance and quality control through advanced systems, technology is at the core of this industry’s operations. It's not just about managing processes; it's about enhancing efficiency, traceability, and reliability. In this digital era, technology isn't just a solution; it's your partner, reshaping how you manufacture and excel in this complex industry.

Krunal Patel

Principal Consultant

Comprehensive Solutions for Your Process Manufacturing Business

Chemical Industry

Our IT solutions provide a comprehensive platform for efficiently managing the production and distribution of chemical products. Tracking raw materials, ensuring batch process integrity, or regulatory compliance, our solution empowers your business to meet the highest standards of quality and safety in the chemical manufacturing sector.

Fuel

The fuel manufacturing and distribution sector requires absolute reliability and compliance with stringent regulations. Our comprehensive tools help manage fuel production, distribution, and regulatory compliance. Track product movement throughout the supply chain and ensure the highest levels of safety and standards.

Chemical Industry

Fuel

Why Choose DynaTech as a Trusted Partner?

Industry Expertise

With a wealth of experience in the process manufacturing sector, DynaTech stands as a pioneer in delivering Microsoft Dynamics solutions tailored to your unique challenges, whether in metal processing, food processing, chemicals, fuels, or commodities.

Tailored Solutions

Harness the power of Microsoft Dynamics 365 solutions fine-tuned explicitly for the Process Manufacturing industry. Our solutions are meticulously crafted to align with the intricacies of your business operations. Our knowledge of Microsoft Dynamics CRM for Process Manufacturing and Microsoft Dynamics ERP for Process Manufacturing is unparalleled.

Sustainable Practices

Aligning with the eco-conscious ethos of Microsoft Dynamics 365, our solutions optimize your operations and contribute to a sustainable future. Our robust solutions enhance your business and minimize your environmental footprint.

Holistic Approach

Our suite of solutions encompasses the entire spectrum of Process Manufacturing operations. From Customer Relationship Management (CRM) to Enterprise Resource Planning (ERP), our Microsoft Dynamics Process Manufacturing ERP solutions streamline every aspect, ensuring a seamless workflow.

Industry Expertise

With a wealth of experience in the process manufacturing sector, DynaTech stands as a pioneer in delivering Microsoft Dynamics solutions tailored to your unique challenges, whether in metal processing, food processing, chemicals, fuels, or commodities.

Tailored Solutions

Harness the power of Microsoft Dynamics 365 solutions fine-tuned explicitly for the Process Manufacturing industry. Our solutions are meticulously crafted to align with the intricacies of your business operations. Our knowledge of Microsoft Dynamics CRM for Process Manufacturing and Microsoft Dynamics ERP for Process Manufacturing is unparalleled.

Sustainable Practices

Aligning with the eco-conscious ethos of Microsoft Dynamics 365, our solutions optimize your operations and contribute to a sustainable future. Our robust solutions enhance your business and minimize your environmental footprint.

Holistic Approach

Our suite of solutions encompasses the entire spectrum of Process Manufacturing operations. From Customer Relationship Management (CRM) to Enterprise Resource Planning (ERP), our Microsoft Dynamics Process Manufacturing ERP solutions streamline every aspect, ensuring a seamless workflow.

Discover DynaTech

Explore the power of DynaTech's technology solutions that can help scale your business to new heights - let us help you get started with a quick consultation!